Fillet Weld Layout Methods: Maximizing Joint Efficiency and Appearance for Structural Honesty

In the realm of architectural design and fabrication, the importance of fillet weld design strategies can not be overstated. By carefully considering factors such as weld account optimization, product choice, joint preparation strategies, welding procedure efficiency, and visual enhancement engineers, fabricators and methods can accomplish a harmonious balance in between performance and look in their bonded frameworks.

Weld Profile Optimization

Achieving an optimum weld account includes a precise consideration of variables such as product thickness, joint configuration, welding placement, and preferred welding speed. Additionally, the option of proper welding parameters, such as voltage, existing, and take a trip speed, is basic in managing the shape and measurements of the fillet weld. Making use of sophisticated welding techniques, such as pulse welding or robot welding, can even more refine the weld account to satisfy specific layout demands and quality criteria.

Basically, weld profile optimization is a basic element of fillet weld design that straight influences the total performance and integrity of welded joints in architectural applications.

Material Option Considerations

When taking into consideration material option for fillet weld style, the compatibility of the base steels is an essential element affecting the architectural stability of the joint. It is important to pick products that not only bonded together properly but additionally possess comparable mechanical properties to make sure the load is equally dispersed in between the base and the weld steels. Welding products with vastly various buildings can lead to problems such as stress and anxiety concentrations, premature joint failing, or fracturing.

Additionally, the atmosphere in which the bonded framework will certainly run should be taken right into account when picking products. Variables like corrosion resistance, temperature changes, and exposure to chemicals can all affect the long life and efficiency of the weld joint. By picking materials that appropriate for the designated application and atmosphere, the general longevity and reliability of the welded joint can be substantially improved.

Consequently, detailed consideration of product compatibility and ecological factors is paramount in making sure the weld joint's stamina, toughness, and general architectural stability.

Joint Preparation Methods

Considering the essential role product selection plays in making sure the structural stability of fillet weld joints, it is vital to implement exact joint preparation methods that maximize the connection in between the base steels. Joint preparation is a vital action that directly influences the top quality and strength of the weld. One essential strategy is the cleaning of base metals to get rid of any pollutants like corrosion, oil, or paint that could top article jeopardize the weld's honesty. This can be achieved with approaches such as grinding, wire brushing, or chemical cleansing.

Furthermore, tack welding the components in place prior to the final weld helps keep positioning and reduces distortion during the welding procedure. By thoroughly following these joint prep work strategies, welders can improve the general performance and visual appeals try this out of fillet weld joints while ensuring architectural stability.

Welding Refine Effectiveness

Reliable welding procedures are vital for attaining optimal productivity and high quality in fillet weld manufacture. Processes like gas metal arc welding (GMAW) and flux-cored arc welding (FCAW) are frequently made use of for fillet welds due to their flexibility and rate.

Moreover, guaranteeing correct tools setup and maintenance is critical for efficient welding. Regular calibration of welding devices, assessment of consumables, and maintenance of soldering iron can avoid downtime and remodel, eventually conserving time and sources. In addition, employing competent welders with knowledge in the details welding procedure being used can substantially affect click to read more efficiency. Well-trained welders are much more skilled at readjusting specifications, fixing issues, and keeping constant weld quality.

Aesthetic Improvement Techniques

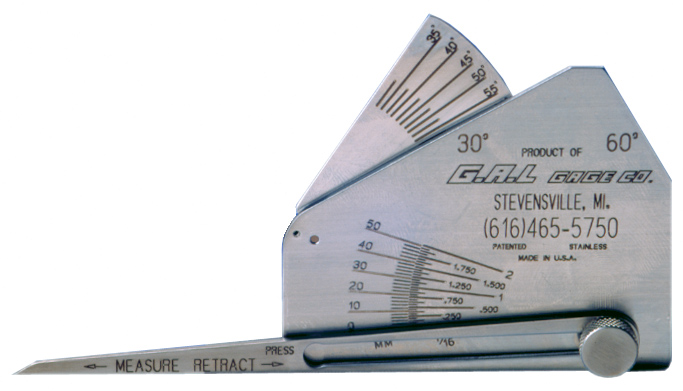

To optimize the quality of fillet weld manufacture, implementing visual improvement techniques can play an important role in ensuring accuracy and accuracy throughout the welding process. Aesthetic enhancement approaches include numerous methods aimed at enhancing the appearance and high quality of fillet welds. One common strategy is the use of back purging systems to get rid of oxidation on the behind of the weld, leading to a cleaner, more visually pleasing finish. Furthermore, using appropriate lights arrangements in the welding location can enhance presence, allowing welders to keep an eye on the weld pool and make sure consistent bead development. Visual aids such as weld dimension evaluates and multiplying lenses can aid in examining weld profiles and dimensions properly. Furthermore, making use of contrasting marking materials or short-lived tacking can assist in straightening and positioning the work surfaces specifically before welding. By incorporating these aesthetic enhancement approaches into the welding process, welders can accomplish not just structurally sound fillet welds however likewise aesthetically appealing results that satisfy sector standards.

Conclusion

To conclude, enhancing fillet weld style entails careful consideration of weld account, material choice, joint prep work, welding process effectiveness, and aesthetic improvement methods. By carrying out these strategies, structural honesty can be improved while also accomplishing visual appeal. It is necessary to focus on both efficiency and aesthetic appeals in fillet weld layout to ensure the overall high quality and longevity of the joint.

By meticulously thinking about aspects such as weld account optimization, product option, joint prep work techniques, welding process effectiveness, and aesthetic improvement approaches, designers and fabricators can accomplish a harmonious equilibrium between performance and look in their welded structures.In the realm of fillet weld design, optimizing the weld profile plays a vital function in making sure architectural stability and performance. The weld profile, which consists of the size and shape of the weld cross-section, directly impacts the distribution of stress and load-bearing capacity within the joint. It is important to choose materials that not just bonded with each other successfully however also possess comparable mechanical residential or commercial properties to guarantee the load is evenly dispersed in between the weld and the base metals - Gauge Fillet Weld.In verdict, maximizing fillet weld style includes careful factor to consider of weld account, material selection, joint prep work, welding process efficiency, and aesthetic improvement techniques